Thermal Technology

Green Extraction Thermal TechNOLOGY

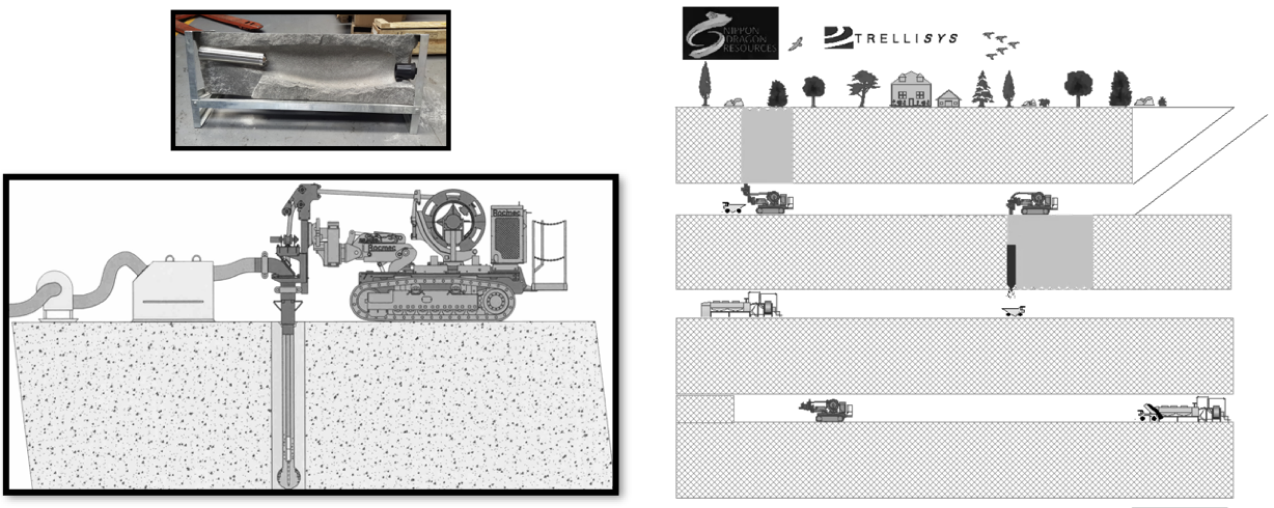

A patented mining method that uses thermal energy applied inside a drilled pilot hole to introduce micro stress fractures into the surrounding rock which allows a spalling process to remove this rock in small chips. Therefore, enlarging the pilot hole’s diameter.

Safety

- No need for people to go into narrow stopes.

- Hardly any explosives with their related safety concerns.

- No potential for explosives damage to surrounding rock, blast cracks disturbing hang wall and related FOG safety issues.

Grade

- Less dilution

- Precision extraction

Efficiency

- Less ore to be moved UG and less crushing,

- Significant reduction in dilution translates it to many advantages such as, smaller drifts, hoists, etc.

Continuous

- No need for blast re-entry times.

Economical

- All the above = less costs overall

KEY ADVANTAGES

Reducution in mining dilution

- Less volume, higher grade, more ounces

- Continuous possible (no blasting)

- Establishment of a free face for blasting operations

- Significant reduction in blast induced damage

Integrated into conventional mining methods

- Fast productivity (4 to 8 spalled meters per hour)

- Spalled chips generated are small (5-20mm)

- No need for primary crushing

- Can be hydro transported

Hole length flexibility up to 25m

- Equipment required is small, simple, and effective

- Hole flexibility from 20cm to 80cm diameter

- Hole diameter can be changed within one hole

- No additional consumables required

Thermal mining method improves safety by moving people away from the exposed span where falls-of-ground are more likely; improves productivity by eliminating re-entry periods mandated when using explosives; reduces dilution by extracting only the ore; and has the potential to increase reserves by making it possible to mine pillars and other isolated blocks-of-ground that may not be economically viable to mine with other methods.

The mining method involves drilling holes within a vein structure, inserting a thermal lance to apply high temperatures inside the hole. The rock then spalls and approximately 30 % of the chips are flushed out of the hole while spalling, with the remaining 70% being cleaned out afterwards.

HOW IT WORKS

1.

Thermal Fragmentation

- A mining method that uses heat to shatter/spall high-grade narrow ore bodies, greatly reducing the use of explosives.

- Extracting the vein with minimal dilution.

- Could be employed as a stand-alone method or as the perfect complement to any conventional mining operation.

2.

Precision Mining

- The art of creating openings of various diameters economically and safely.

- Conclusive tests of hard rock fragmentation conducted around the globe.

- Thermal fragmentation is a highly-precise mining method for creating large openings and extracting ore.

3.

Surgical Precision

- Enlarges a 15cm hole up to 80cm and as much as up to 110cm in a very good ground condition.

- Operates at any angle and dip, up to 25 metres

- A 100 cm diameter hole can produce between 8-10 tonnes per hour

- Using control blasting between holes can multiply the per tonne/per hour productivity

RESEARCH & DEVELOPMENT

An extensive R&D programme is currently ongoing and will continue for the foreseeable future. Participants involved in the programme:

– COALIA/College center for technology transfer/Thetford Mines College

– LBM Quebec

– Nemesis Intelligence

– SEMM Geoservices

– Goldminds Geoservices

– MaXem (South Africa)

The objectives of the programme include but are not limited to:

– Enhance performance of the thermal units;

– Geology rock identification and fragmentation controlling factors;

– Effective fragmented rock recovery process;

– Spallability index to classify fragmentability vs sample geology:

– Categorisation/quantification of fragmentated ore ‘chips’ (weight, quantity, shape etc) produced by Spallability tests in order to standardize testing in South Africa and Canada;

– In situ rock characterisation and geology identification prediction;

– Development of measuring devices for fragmented hole characterisation;

– Development of a scanning device for small and irregular fragmented holes to provide a 3D

image to calculate production, evaluate fragmentation quality/quantity and geology;

– Developing a 3D web/Cloud based viewing application to visualize fragmented hole, calculate

performance;

– In hole imaging and predictive rock composition and localisation in drilled holes;